Tech

RTV COLORS AND WHEN TO USE THEM

Originally Published in Issue 34 of 4Low Magazine

Make sure to subscribe to get the newest issues of 4Low Magazine right to your mailbox. CLICK HERE

By Joel Moranton, with expert Curtis Haines of Permatex

Photos courtesy of Permatex

This post contains affiliate links, if you purchase something through those links, 4Low Magazine may earn a commission – at no cost to you.

Have you ever wondered why there are so many different colors of RTV and when to use them? If you’re like me, you wonder, but just grab Ultra Grey and move on with your life. I finally decided to educate myself about RTV and find out what I’ve been doing wrong. Let’s start with: What is RTV? RTV stands for Room Temperature Vulcanization, keep reading to find out why and how to use it.

I found most information available online is not very helpful. I reached out to my professional mechanic friends to see what they knew, while they all had their own opinions, none were willing to go on record to tell me when to use each color of RTV and why. So, I went right to the source, Permatex, the makers of RTV, to help me.

Our RTV expert at Permatex is Curtis Haines, formerly the Technical Service Manager at Permatex, now the Inside Sales Manager. It was a blast chatting with him, and I know we only scratched the surface of his knowledge. Let’s dive into what Curtis shared with me during our conversation.

While we are going to focus mainly on RTV in this article, Permatex has a wide array of products that solve specific problems. Permatex is over 100 years old and is still selling its original product, Indian Head Gasket Shellac Compound. With this rich history, many of Permatex products and the ways they are used are passed down from generation to generation. The particular Permatex product you like to use and love is likely due to a family member teaching you how and why to use it. This is one of the reasons Permatex has been in business for as long as they have. Their products all work so well that even if you are not using them for the exact designed purpose, it still has a high probability of working. Most of us just buy Ultra Black or Ultra Grey for just about every application. 20-30 years ago, you might have just grabbed Blue or Grey RTV, and now the next generation will be picking up Permatex Optimum Black or Grey. What is the difference between Standard, Ultra, and Optimum? We will be answering that and the color differences in this article.

BLACK RTV

Permatex currently has three black RTV products. Black Silicone Adhesive Sealant, Ultra Black, and Optimum Black. There is also The Right Stuff, but we will talk about The Right Stuff later.

Black Silicone Adhesive Sealant part number 81158 – This RTV is not recommended for engine applications. It is not oil resistant; you don’t want to confuse this product with the Ultra Black. The Black Silicone Adhesive Sealant can be used for window sealants, water sealing, and for electrical repairs. It is great for anything that would experience a jarring impact because it has high tensile strength.

Applications listed from Permatex includes indoor/outdoor sealant, bonds, repairs, mends and secures glass, metal, plastics, fabric, vinyl, weather stripping, and vinyl tops. Protects and repairs electrical wiring. Waterproof and flexible.

Temperature range -75°F to 450°F (-59°C to 232°C); resists water, weather, and vibration.

Ultra-Black Maximum Oil Resistance RTV Silicone part number 82180 – This is the best-selling, flagship product. It is best used for any application that comes in contact with engine oil. It is good for bonding two types of metal together because it can flex to ten times its original shape. For example, joining a steel and aluminum part, the two metals will heat and cool at different rates causing them to expand away from each other.

Applications listed from Permatex include valve covers, oil pans, intake manifold end seals, timing covers, differential covers

Temperature range -65°F to 500°F (-54°C to 260°C) intermittent; resists auto and shop fluids and vibration.

Optimum Black part number 27037 – The Optimum line is the next evolution of Permatex RTV. Just as the Ultra line was an improvement over the Standard, the Optimum line was designed to evolve with the automotive industry. As auto manufacturers continue to innovate and use different materials, Permatex continues to test and improve the line to make sure it can handle the demands. Like Ultra Black, Optimum Black has maximum oil resistance, but it has even more flex, up to 15 times. The extra flexibly of the Optimum Black and its heat dissipation properties allow it to retain the bond between different materials. Optimum Black should be used to bond two, unlike materials where oil is present.

Applications listed from Permatex include the same as Ultra Black but for newer, lightweight and premium components, where maximum oil resistance and high flex is required because of dissimilar metals.

High-Temperature performance up to 500°F

Permatex currently has three Grey RTV products, Ultra Grey, Ultimate Grey, and Optimum Grey. Again, there is also a Right Stuff Grey, but we will cover that later.

Ultra Grey Rigid High-Torque RTV Silicone part number 82194 – Ultra Grey was born to handle the demands of import engines that run at higher RPM with more vibrations and have tighter tolerances than domestic engines. “Ultra Grey is the best thing since sliced bread”.

Just like Ultra Black, it is oil resistant and can withstand coolant and steering fluid. It features a higher density, allowing it to handle the vibrations and high tensile strength to bond between tighter tolerances.

Applications listed from Permatex include valve covers, oil pans, automatic transmission pans, intake manifold end seals, timing covers, water pumps, thermostat housings.

Temperature range -65ºF to 500ºF (-54°C to 260°C) intermittent; resists auto and shop fluids and vibration.

MotoSeal 1 Ultimate Grey part number 29132 – Ultimate Grey is the only RTV that is designed to resist gasoline. This makes it the only RTV you want to use in an engine with Gas and Oil mixtures like 2-stroke engines.

Applications listed from Permatex include Transmission case halves, valve covers, center and end covers (transmissions), crankcase halves, cam covers, timing chain cases, primary drives, side covers, and clutch housings.

Temperatures: 350°F (177°C) continuous, 400°F (204°C) intermittent.

Optimum Grey part number 27036 – If you could only have one RTV – this would be the RTV to have. Permatex looked at the one feature that Ultra Grey was missing, heat resistance, and engineered Optimum Grey to withstand 650°F consistent temperature with 700°F intermittent. It still has all the great features of Ultra Grey but now can handle higher heat.

Applications listed from Permatex include the Same as Ultra Grey with the addition of high heat parts like exhaust manifolds/headers and slip-fit exhaust parts.

Temperature range -65°F to 700°F (-54°C to 371°C) intermittent

Permatex currently has three Red RTV products, Red High Temp, Ultra Red, Optimum Red.

High Temp Red RTV part number 81160 – This is the original high-temperature resistance RTV. It does not have the tensile strength as the other RTVs. The High Temp Red is great for exhaust application. This RTV is not sensor safe since it is an Acetoxy base compound. This product cures by off-gassing. This off-gas can release impurities into your system that could stick to your sensors, causing them to read incorrectly. It’s unlikely, as it would take 1000’s of heat cycles before it could potentially cause an issue.

Applications listed from Permatex include Valve covers, oil pans, timing covers, and thermostat housings.

Temperature range -65ºF to 650ºF (-54°C to 343°C) intermittent; resists auto and shop fluids.

Ultra Red part number 81630 – Ultra Red is one of Permatexs’ newest products. Permatex recognized the one drawback to the High Temp Red RTV was not being sensor safe. Ultra Red was engineered with an Oxime base that cures like most RTV by pulling in oxygen; thus does not off-gas. Ultra Red has more adhesion than High Temp Red.

Applications listed from Permatex include: Same as High Temp Red but is safe for sensor applications.

Temperature range -65ºF to 650ºF (-54°C to 343°C) intermittent; resists auto and shop fluids.

Optimum Red part number 27038 – Optimum Red features a higher density with better adhesion that allows it to handle high pressures, making it perfect for forced injections applications.

Applications listed from Permatex include the Same as Ultra Red with the addition of higher pressure applications.

Temperature range -65ºF to 750ºF (-54°C to 343°C) intermittent; resists auto and shop fluids.

Ultra Copper Maximum Temperature RTV part number 81878 – Just like Optimum Red, Ultra Copper is great for high-temperature applications where pressure builds up. Ultra Copper is specifically designed for extended high-temperature exposure like you find in a race engine application.

Applications listed from Permatex includes the Same Optimum Red with better constant high-temperature exposure.

Temperature range -65°F to 700°F (-54°C to 371°C) intermittent; resists auto and shop fluids and vibration.

BLUE RTV

Sensor-Safe Blue RTV part number 80022 – Blue RTV is a great all-around gasket maker. It is kind of like the adjustable wrench in your toolbox. It can do a lot, but it’s not always the best tool for the job. It was the predecessor to Ultra Black, and can be used much the same, but Blue should not be used with Gear oil.

Applications listed from Permatex include Valve covers, oil pans, timing covers, water pumps, and thermostat housings.

Temperature range -65°F to 500°F (-54°C to 260°C) intermittent; resists auto and shop fluids.

SPECIALTY RTVS

Permatex also has several RTV’s that expand the performance of their base products with specific formulas for each application. “Product-specific formulas for specific applications” They engineer each one of these products by analyzing the fluid or air type (intake or exhaust) that the product would be exposed to and formulating the product to seal against those parameters. For example, the Ultra Synthetic RTV is formulated to resist breaking down when exposed to any full synthetic engine oil. If you are using the top-of-the-line fluids for maximum performance, then you want the RTV that can handle any of the additives in the top-of-the-line fluids. The Specialty RTVs for Permatex include Automatic Transmission, Gear Oil, Water Pump, and Ultra Synthetic.

DO AND DON’TS

How should the surface be prepared for the RTV application? To get the best adhesion, make sure all old gasket material, oils, and other fluids are removed. Brake Parts Cleaner is perfect. Do not use alcohol or acetone as they are solvents. They can fill the pores of the metal surface and compromise the RTV’s ability to adhere.

Should RTV be used on either side of a precut gasket? There is nothing wrong with using RTV on either side of a precut gasket. It is also not necessary as the properly design RTV is formulated to be the gasket. Think of it this way, you are using RTV to chemically bond two surfaces. When mating two-parts together, you have two surfaces to bond together; by including the gasket, you now have four surfaces to bond together. The precut gasket is going to be the weak link in this scenario.

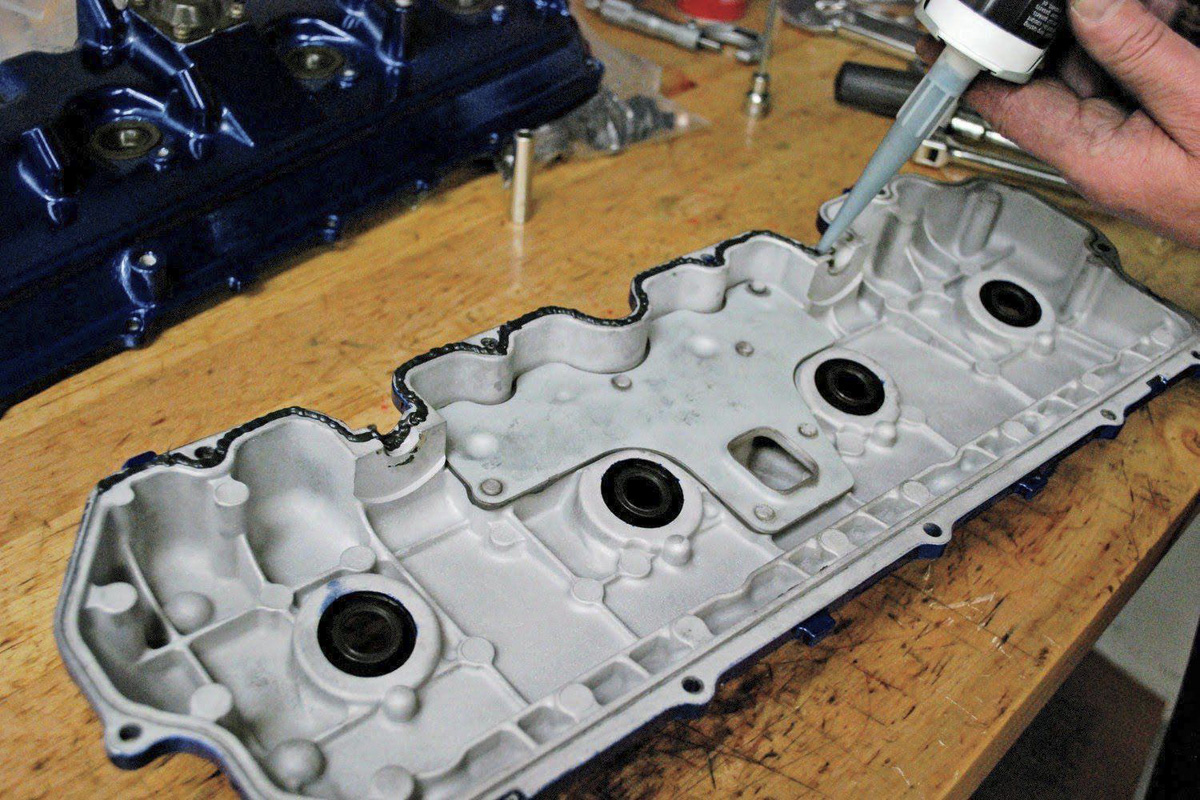

How do you know how much RTV to apply?

To properly apply RTV, you should have a continuous spaghetti noodle in the center of the matting surface. The diameter of the spaghetti noodle depends on the thickness of your matting surface. Contrary to popular belief, RTV should not be smoothed out before installing. When smoothing out RTV, you can create peaks and valleys in the RTV that can cause an uneven application. Make sure you are not a victim of “Silly Monkey Syndrome” you don’t need to squeeze the RTV tube like a silly monkey strangling a banana in a cartoon. This can cause RTV to “squeeze-out” on the inside of the engine and block off your oil pick-up.

What is the proper set-up procedure of RTV?

Apply one continuous bead of silicone, circling every bolt hole. Assemble all parts with bolts finger-tight. Allow the RTV to sit for one hour. Then after an hour, all bolts should be torqued to specification. Fluid should only be introduced 24 hours after installation. Do not use heat lamps or heat guns to speed up this process – the product cures by pulling moisture from the air. Do not apply water to the RTV while it is curing. Simply exercise proper patience. If you can’t wait, read the next paragraph. These guys have thought of everything.

Set-up time brings us to the final RTV line available from Permatex, Right Stuff. Permatex listened to its customers and did everything they could to solve their problems. The set-up of RTV is not suitable in a professional setting, as there is no way to keep a vehicle tying up a rack while RTV cures. Permatex was able to formulate Black and Grey RTV with a 1 minute set-up time. After the Right Stuff sets for one minute, you can add oil and move onto the next project. To achieve this, the product is very dense, so it needs assistance to come out of the cartridge tube (caulk gun) or aerosol can (think cheese-whiz). Popular opinion dictated the aerosol is not the favored choice, so Permatex answered the call with Right Stuff 90min. They were able to get the set-up time down to 90 minutes and offer the ability to squeeze out of a standard tube. All the features and benefits of The Right Stuff with the preferred packaging of their everyday users.

WRAP UP

I hope you learned a bit about when and why you should use each color of RTV. I know I am super thankful for Curtis’s time in answering my questions. I now feel like I have a good idea of when I should use each color and type. Check out the quick summary in the sidebar for how I am going to use RTV on my vehicles.

The most important point you can walk away with is:

- Black RTV can flex, allowing it to retain its bonds between two different material types that will heat and cool at different speeds.

- Grey RTV has higher density when cured for higher vibration resistance and tight tolerance applications.

- Red RTV is for exhaust and high heat applications.

- The specialty RTVs are perfect for holding up to the demands of their specific applications.

- Do not smooth out your RTV!

ARTICLE SUMMARY

There is a lot of information in this article, here’s a quick summary of what I learned from Permatex and how I will be using RTV on my vehicles.

Optimum better than Ultra

Right Stuff has a quick set-up time without sacrificing quality.

Black: Flexible for bonding different materials and high oil situation, but standard Black is not for engine applications.

Grey: Great for just about everything. Best for high vibration and tight tolerances.

Red: High Heat applications

Blue: Kind of like your adjustable wrench, can do a lot, but not always the right tool for the job.

How I will use RTV:

Optimum Black: Oil pans, Oil Pumps, 22RE timing covers, High oil contact areas.

Optimum Grey: Water Pumps, Thermostats, timing covers, and valve covers. It will be my go-to RTV for most of the maintenance work I do.

Automatic Transmission RTV: Automatic Transmission applications

Gear Oil RTV: Differentials and transfer cases. Optimum Black if Gear Oil RTV is not available.

Ultimate Grey: All 2-stoke engines.

Optimum Red: All exhaust and turbo applications

If the Optimum series is not available, Ultra is great.

If I need to have a quick turnaround job, The Right Stuff is key!

I will no longer smooth out my RTV, just a simple continuous spaghetti noodle.

No need to use precut gaskets with RTV; just use the right RTV for application.