Tech

Lock it or lube it?

By Tim Lund

Originally Published in Issue 24 of 4Low Magazine

Make sure to subscribe to get the newest issues of 4Low Magazine right to your mail box. CLICK HERE

Thread locking compound (aka Loctite) and anti-seize seem to be self-explanatory, yet they are often misunderstood and, in the 4×4 world, they are definitely not used to their maximum potential.

Many people’s view is that anti-seize is used to keep threads from seizing and thread locker is used to keep things tight. For the most part that statement is true. However when we dig a little deeper we’ll find that they are kind of similar even though they are very different. Let’s start with some definitions and go from there.

Thread sealants or thread locking compounds are basically adhesives that are used to SEAL the threads and help keep them from loosening.

Anti-seize compounds are basically lubricants that SEAL the threads to help keep the threads free from corrosion and seizing together.

Now those are very basic definitions, but you can see that they are similar in the aspects that they both SEAL the threads to do their job. How they go about sealing threads and the use of them are very different.

Thread Locking Compound:

Thread locking compound It is an anaerobic sealant (doesn’t need air to set) used to bond fasteners together. Not only does it bond the fasteners together, it also seals the threads of the fasteners to keep air, water and other contaminants from getting inside and causing corrosion. That’s right, it seals out the bad stuff to help keep the threads from seizing due to corrosion. So think of it as an anti-seize that helps keep the fasteners tight.

Most everyone is familiar with the name Loctite, that brand name is so well known it is used just about any time someone refers to a thread locking compound, whether it be genuine Loctite or not. Just like the name Kleenex is used for facial tissues no matter what brand it actually is.

Thread locking compound should be used on the threads of any fastener that needs to be kept stationary and is subject to moving loads or vibration, which of course is just about everything on your 4wd. As a bonus, since it seals the threads from contaminants you can view it as an anti-corrosion tool too.

Two most common grades:

Blue: Medium strength thread locking compound. This is the most commonly used variant as it is good enough to lock most fasteners tight. Fasteners “locked” with blue can typically be removed with hand tools.

Red: High strength thread locking compound. These are used in areas where high strength locking is desired and will typically require heat to soften the adhesive for easy disassembly. Red threadlock needs around 500 degrees of localized heat to soften the compound to make it easy to separate fasteners. So a quick blast on the bolt head or nut with a torch will usually do the trick.

Two other grades that we could use:

Green: Often used to “lock” in sleeves and bearing races, especially in aluminum housings.

Purple: This newer flavor in thread locking compounds is rated low-strength and is perfect for those smaller fasteners that tend to come loose with vibration, think small accessory mounting screws and trim screws.

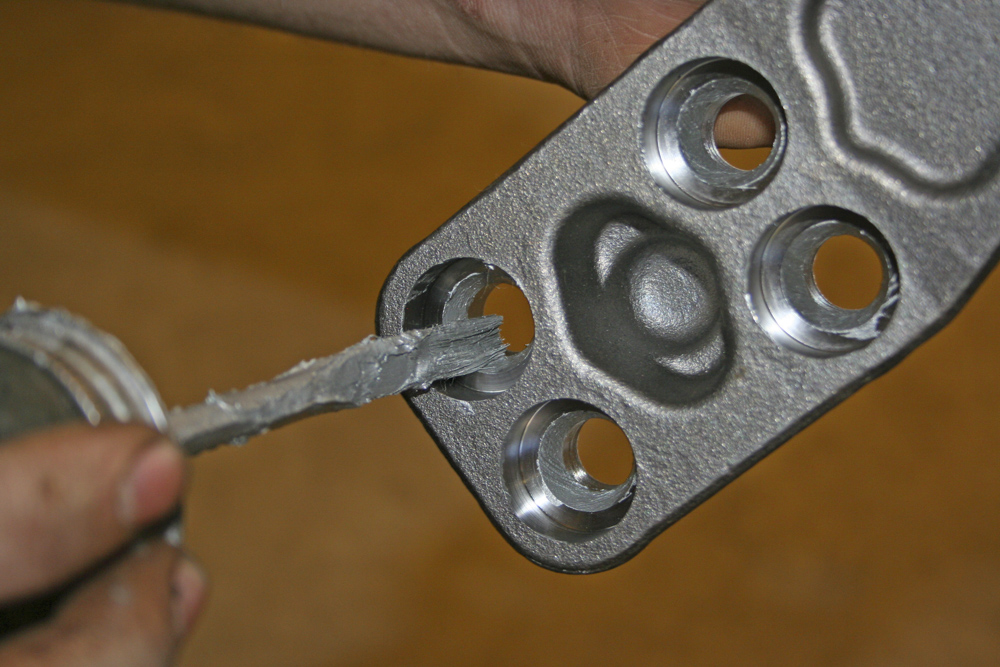

How-to use thread locking compound: Make sure the fasteners are clean and dry with no corrosion on them. Some grades are more tolerant of oil and contamination, but clean and dry are always your best bet.

Anti-seize Compound:

Anti-seize is a thread lubricant that seals the threads from contaminants and protects the threads from seizure due to extreme pressures, dissimilar metal corrosion and high heat fluctuations, such as the heating and cooling cycles of an exhaust system.

What is Anti-seize: Anti-seize compounds are basically a two stage lubrication paste. The first stage or base is typically a high grade grease that lubricates the parts up to the maximum temperature of the grease (400°-ish). The second part is lubricating solids that are suspended in the grease and good for temperatures of 1600° degrees or more.

Common grades of anti-seize:

Silver (aka aluminum): The typical silver formula contains aluminum, copper and graphite solids and is typically good to about 1600° F. Use silver anti-seize for engine bolts, brake anchor pins, suspension bolts and u-bolts.

Copper: The typical copper formula contains copper solids and is good for temps up to 1800°. Copper anti-seize is also a good conductor of electricity. Use copper anti-seize for high heat fasteners such as exhaust manifold bolts and any application that has electrical conductivity such as spark plugs and O2 sensors.

Other grades: There are other grades available, including nickel, food grade and even nuclear grade. In reality, silver and copper are the only two you need in your garage.

How to use anti-seize: Go sparingly, with anti-seize a little goes a long way. Make sure the threads are clean and dry and you are using the correct formula for your application.

Reduce torque values: Most threaded fasteners are rated for a dry torque. When you apply anti-seize you are lubricating the threads making it easier for them to slide against each other, which could lead to over torquing the fasteners. It is recommended to reduce torque values by 10-25%. If it is a critical application, please contact the manufacturer for recommended lubricated or “wet” torque values.

In the end it’s best to have the mindset that you should use thread locker or anti-seize on just about every fastener in your 4×4. Which one where? Well, that old axiom applies here: if you don’t want it to move, use thread locker. If you don’t want it to rust together, use anti-seize. There are always exceptions to the rules and this is just a little look into the world of thread sealants.