Originally Published in Issue 32 of 4Low Magazine

Make sure to subscribe to get the newest issues of 4Low Magazine right to your mailbox. CLICK HERE

By Christian Sturtz, [email protected]

Photos by Christian Sturtz

Having a good recovery point and an adequate winch is a necessity in any off-road vehicle – not only for your safety, but also for the protection of other vehicles with you. Not having available recovery points could lead you to a delay in recovery time, placing yourself and others in increased danger. Also, just because a recovery point is easily accessible doesn’t mean its safe!

It is crucial to have strong recovery points that are tied into the chassis of the vehicle, either directly or indirectly (for example, a D-ring mount that is welded to a bumper and bolted to the vehicle chassis).

When choosing a winch, look for something that is load-rated at a minimum of 1 ½ times the weight of your vehicle, it’s even better if you steer on the cautious side and shoot for two times the weight of the vehicle. Do your research and find something that has good reviews, is dependable, and has readily available product support.

In this article, we are going to overview the installation of a KD Fabworks’ mid-width bumper with a trail bar on a 05 Jeep Wrangler LJ. Along with the bumper, we will be installing a few other products by KD Fabworks, including a front license plate mount and a steering box skid plate that ties into the bumper. To complete this install, we will be installing a 12,500lb Talon Winch by Superwinch. KD Fabworks makes front bumpers for YJ, ZJ, TJ/LJ, and JK models. The TJ/LJ bumper is available in a 43” width crawler and a 49” mid-width; both are available with or without trail bars. We chose to go with the mid-width and the trail bar, with light tabs, for additional protection.

A great feature of our KD bumper is that it has integrated recovery points and can accept standard or vertical type winches (such as the Warn 8274-50). The recovery points are robust and easily connected to a D-ring or soft shackle.

We started the install by unplugging the factory fog/flood lights on both sides. Next, we unscrewed the six Torx bolts and removed the bumper. Then the plastic cover for the sway bar was unbolted and removed. Finally, we removed the front bolts for the sway bar bushing mounts- we chose to completely remove the sway bar at this time because we are changing to a different type setup in the near future. Before the sway bar was removed, the bumper was slid into position to check bumper fitment with the stock sway bar. We also checked to see whether the winch mounting bolts were accessible with the bumper in place – they are not. So, the winch will have to be bolted to the bumper, and then the bumper will be installed.

Before the sway bar was removed, the bumper was slid into position to check bumper fitment with the stock sway bar. We also checked to see whether the winch mounting bolts were accessible with the bumper in place – they are not. So, the winch will have to be bolted to the bumper, and then the bumper will be installed.

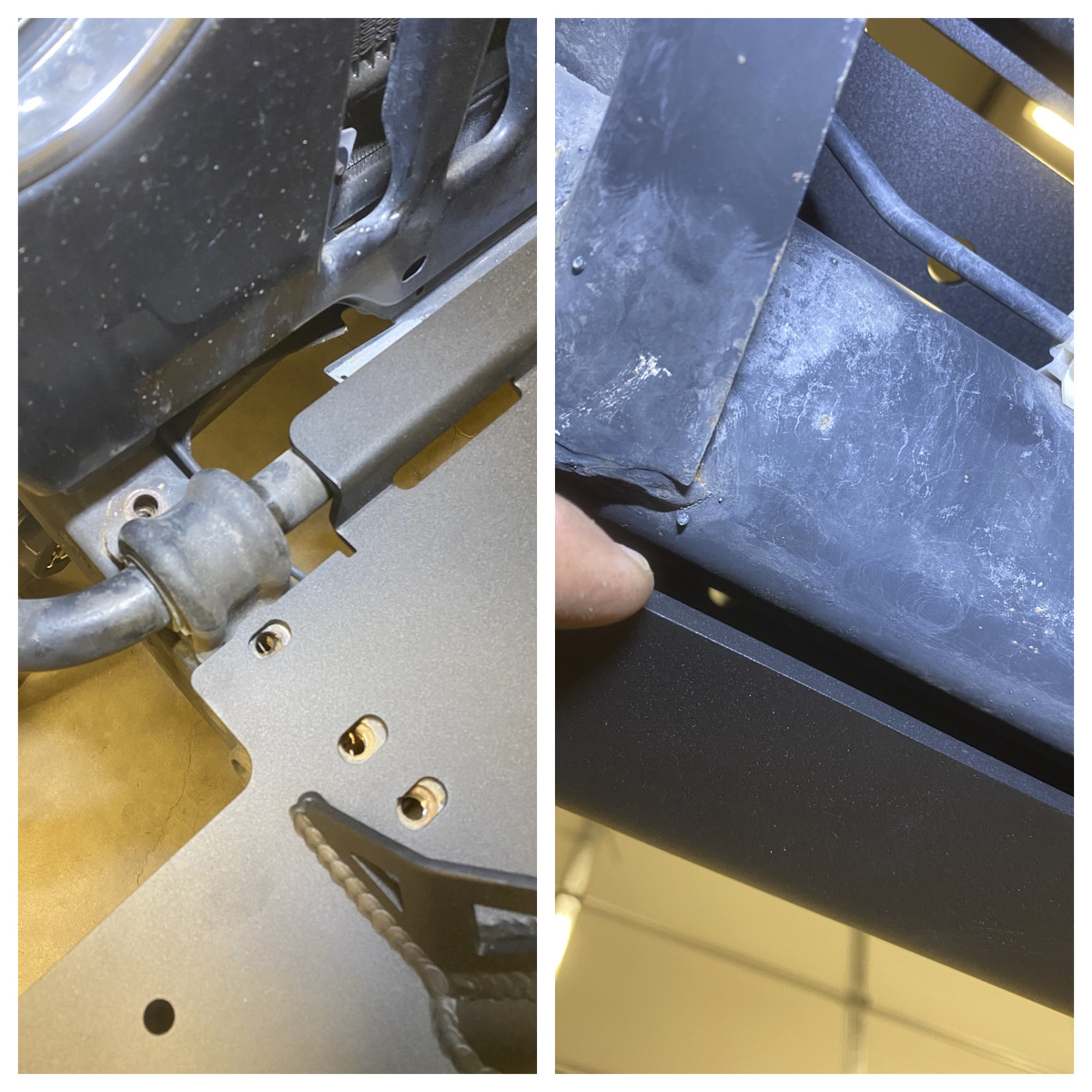

The KD Fabworks bumper and fairlead mount allow you to mount the winch in two different positions. We had to use the front position (rear holes) because we were using the optional front plate mount. We started by sandwiching the plate mount between the fairlead and the mount, then bolting them together with the supplied Allen bolts. The fairlead mount is designed to be placed between the bumper and the winch. Next, the captive nuts were put into their holders then the winch bolts were run from the bottom up, through the bumper fairlead mount, and into the captive nuts in the winch. Once they were all started, the four bolts were tightened. Make sure all the bolts are at least flush when tightened with the captive nuts, if not, get longer bolts (same grade) that do not bottom out.

The bumper was slid into position and the supplied bolts were loosely started, along with the removed sway bar bolts. Next, the lowest steering box bolt was removed and placed through the steering box skid plate. The additional supplied bolt/nut was installed in the bumper and both steering box bolt and the new bolt/nut were tightened. Finally, to finish up the bumper install, the six bumper bolts and sway bar bolts were tightened.

Wiring for the winch is as simple as it gets- black lead to the negative/ground and red lead to the positive/battery +. We chose to place some heat shield tubing over the leads to protect them from abrasions and heat. A good way to get a clean look is to use heat shrink tubing on the ends of the heat shield; this looks great and prevents the tubing from fraying and moving. Next, we routed the leads safely through the grill, down the frame rail, and hooked them up. Then we installed the supplied hook, some D-rings, and an isolator kit by Daystar. Finally, we tried it out. This Talon winch by Superwinch is packed with some great features- a robust design, synthetic rope, heavy-duty lighted controller, and Hawse fairlead.

Sources:

KD Fabworks

P.O. Box 1473

Oregon City, OR 97045

888.535.1580

www.kdfabworks.com

Super Winch/ Westin Automotive

320 W. Covina Blvd.

San Dimas, CA 91773

800.323.2031

www.superwinch.com

Daystar

841 S. 71st Ave.

Phoenix, AZ 85043

800.595.7659

www.daystarweb.com

GEARWRENCH

APEX Tool Group

910 Ridgebrook Rd. (Suite 200)

Sparks, MD 21152

800.688.8949

www.gearwrench.com

Parts Used:

KD Fabworks:

97-06 TJ Front mid-width bumper with trail bar and light tabs

Hawse fairlead license plate bracket (BRK-LPH)

Steering skid plate (TJ-2001)

Superwinch:

Talon 12.5SR (1612201)

Daystar:

D-ring isolator kit (KU70057BK)