Tech

FREE UP YOUR SPRINGS – Adding Longer shackles

Originally Published in Issue 36 of 4Low Magazine

Make sure to subscribe to get the newest issues of 4Low Magazine right to your mailbox. CLICK HERE

By Christian Sturtz, [email protected]

Photos by Christian Sturtz

Stock length shackles sometimes cause aftermarket springs to bind and not move or cycle smoothly. The CJ-3A we’ve been working on had stock “C” type shackles with metal to metal contact on both the inside of the leaf springs and the inside of the hangers, which can cause binding. The short length also limits the amount of motion the spring has. The shackle pulls on the hanger under compression and doesn’t pivot the shackle, which also happens on droop.

When changing the shackle length, you have to look at several things before changing them out. Are the shocks going to work? A longer shackle changes the ride height. Sometimes a longer shackle will lower the ride height depending on the shackle hangers’ design and positioning. On this CJ-3A, the longer shackles will raise the ride height. We need to verify the shocks are long enough and still have enough travel that they will not bottom out at full compression.

The second thing to check is proper height bump stops. The bump stops need to be long/high enough that they don’t allow the spring to go into a negative arch or, if so, very little. Cycling a leaf spring into a negative arch dramatically reduces the life of the spring and can cause fatigue, as well as breaking.

The third thing to check is what the longer shackles will do to the steering geometry and driveshaft angles. Longer shackles on the front will remove caster and rotate the pinion up more towards the floor. It will also increase the drag link’s angle, which can result in a more pronounced bump steer. It may be necessary to install caster shims under the spring pads to correct the caster and driveline angle. The steering may need to be adjusted or modified to work at optimal performance. On this application, longer rear shackles will rotate the pinion up towards the floor, which may require shims to correct.

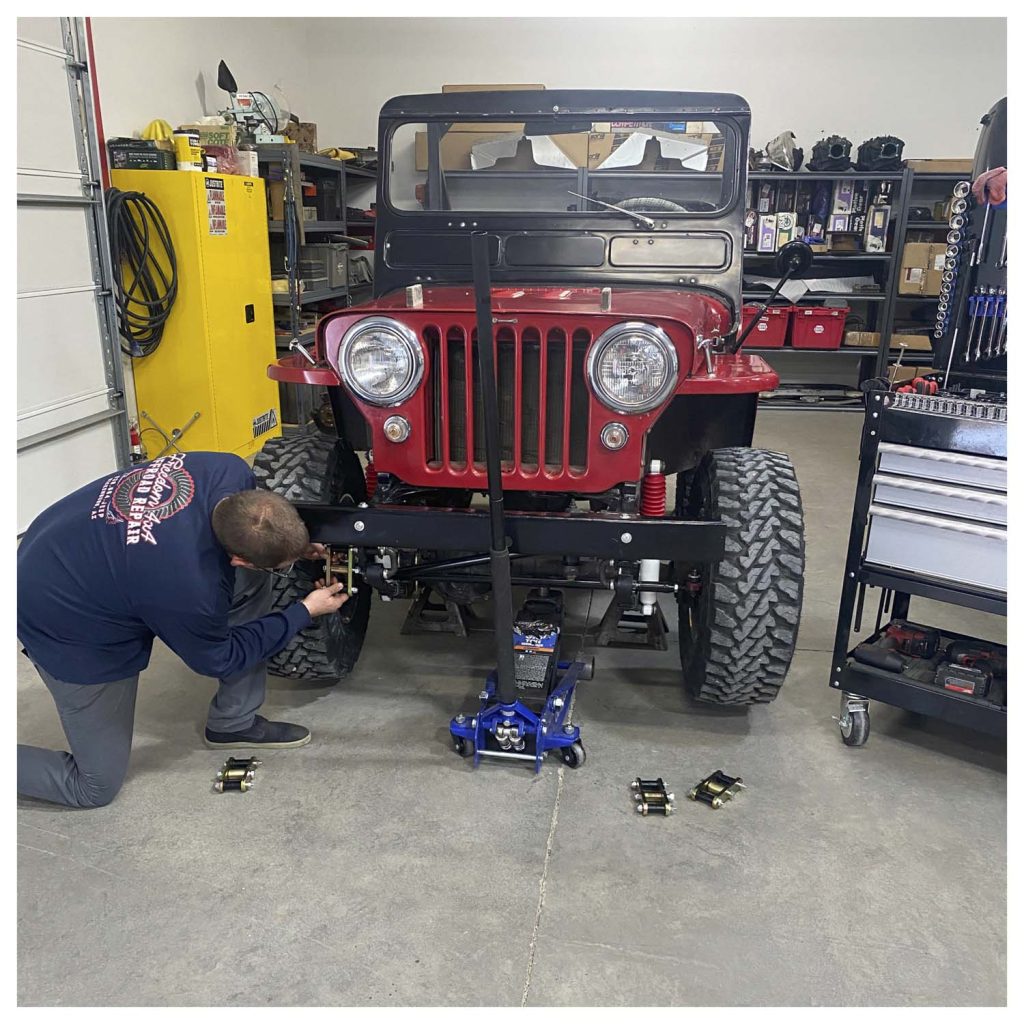

We started by supporting the vehicle with jack stands on the frame right behind the fixed spring hanger. We supported the axle with a jack; then removed the “C” shackles. On our CJ-3A, some of the shackle bolts are left-handed and some are right-handed- if they don’t come loose try turning the opposite direction. Next, the holes in the shackle mount and leaf spring were cleaned out, new included bushings and sleeves were lubed with silicone-based grease, and finally, the new bushings and sleeves were inserted into the springs and shackle hangers.

We then let the axle fully droop and hang by the shocks. At full droop, the shackles were too long to fit without pushing the spring down. So, we removed the topside of the shock and bolted the shackles into place. At full droop. we could see the shock was 1-2” short. Knowing that the rear shocks are longer, we thought we would try one of them, which would give us a good starting point. After installing one in place and taking some measurements, it worked perfectly. Finally, the front end was set on the ground, and the shackles were tightened.

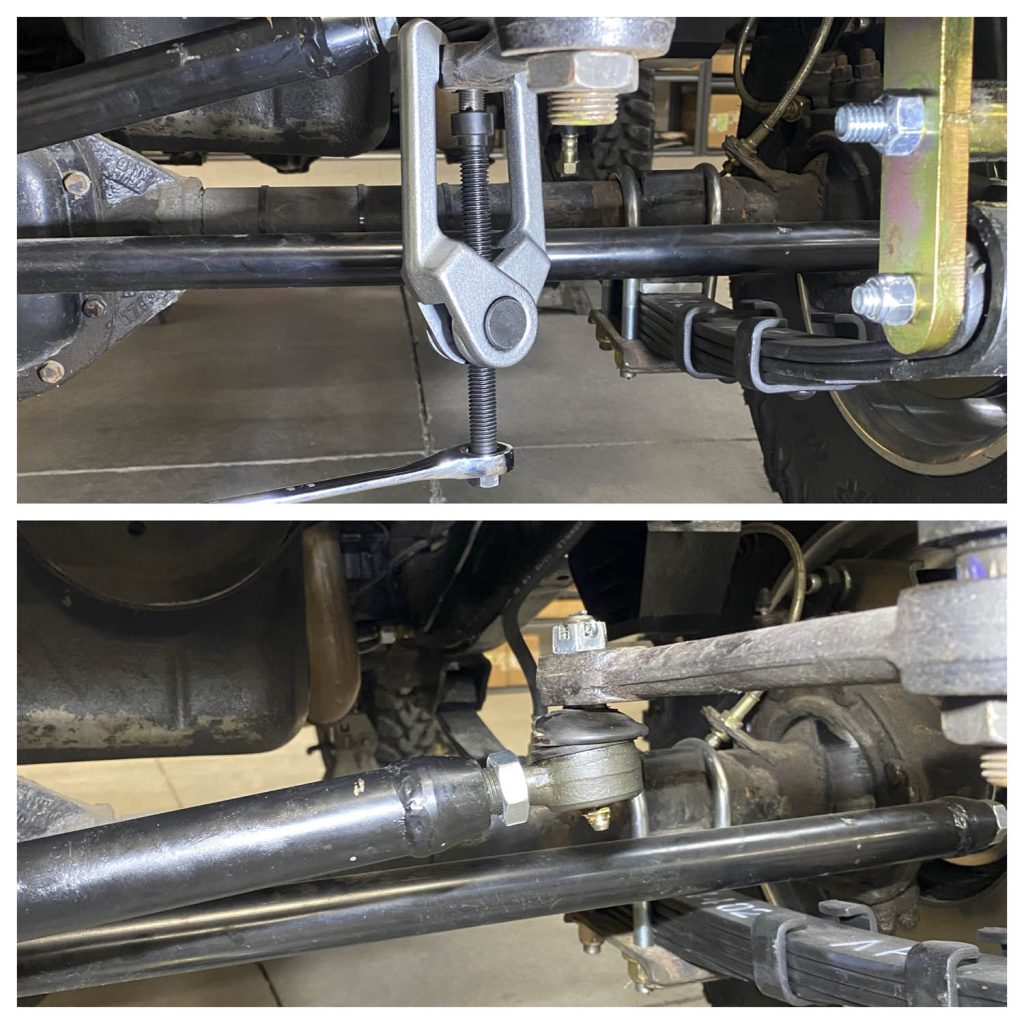

After checking the front caster and pinion angle, it looked pretty close with the 2-degree shims that we put in during the lift install. However, the drag link angle needed some work. The pitman arm we used on the Saginaw conversion was initially reamed from the bottom up. So, we flipped the tie-rod end over and re-centered the steering wheel.

For the rear, the install is almost identical. We checked to make sure the pinion angle was correct after the shackles were installed. It turns out the pinion angle was better than before the install. The rear shocks on early Jeeps are at a decent angle and are not in a 1:1 ratio, which means there is not as much shock length change throughout the travel. The rear shock length was still correct after the shackles were installed, and only two new shocks, part #RS55113, were needed for the front. Now the Jeep has a little more height for tire clearance, and the longer shackle length and spring bushing design helps the springs to move more freely.

Parts Used:

Mountain Off-Road Enterprises:

2) Shackle Sets (LS9033)

Rancho Suspension:

2) Shocks (RS55113)

Sources:

Mountain Off-Road Enterprises

685 Highway 92

Delta, CO 81416

877-533-7229

www.mountainoffroad.com

Rancho Suspension

1 International Dr.

Monroe, MI 48161

800-325-8886

www.gorancho.com

GEARWRENCH

APEX Tool Group

910 Ridgebrook Rd. (Suite 200)

Sparks, MD 21152

1-800-688-8949

www.gearwrench.com