Builds, Subscriber Spotlights

Dude, that’s a nice rig.

Originally Published in Issue 33 of 4Low Magazine

Make sure to subscribe to get the newest issues of 4Low Magazine right to your mailbox. CLICK HERE

Story by Bryan “Opie” Bennett

Photos by Bryan “Opie” Bennett and Kelly Marquis

My wheeling buddy Phil Weeks and I have known each other for going on 16 years. In 2006 or so, we went wheeling maybe two weekends a month, the whole year. On one of those trips, possibly on the Swamp Lake trail in California’s Sierra Nevada mountain range, east of Fresno, CA, I distinctly recall Phil saying that he wished that someday, someone would come up to him and say “Dude, that’s a nice rig.”

At the time, we were wheeling in modified Cherokees on 35’s, driving to the trails, taking body damage on and losing glass with each trip – and to be honest, looking back on it; we didn’t have the nicest rigs. That has been the inspiration for decisions and the ‘measuring stick’ as I’ve been building this car.

Phil’s current Cherokee chassis was built in stages. When terrain and money and downtime all collided requiring upgrades – you know, the one that everyone has. Cut a little off, add something new, another time cut more, add something else back, ending up with a firewall and some plated factory uni-body pieces, some tube, and a lot of great buggy parts hidden in all the compromises along the way. When Phil decided it was time to start fresh, I jumped at the chance to build another full-tube buggy. Goals were to re-use as many of the Cherokee buggy pieces as possible and build a 4-seater, Rubicon camping, Hammers cruising, WE Rock Pro-Mod legal car. I had recently performed the same recycle of good parts into a tube chassis, building the ‘Banquet’ buggy in 2017. Competing at many of the WE Rock western series events in 2018 and 2019 allowed me to work out some kinks. My first call was to Patrick McAuliffe at Those Guys Rod and Customs in Bremerton, WA. As a long time friend, former WE Rock Stock Mod competitor, and professional automotive fabricator, he was a huge help in building my pro-modified car. Patrick and I agreed on shop space, tooling use, and materials.

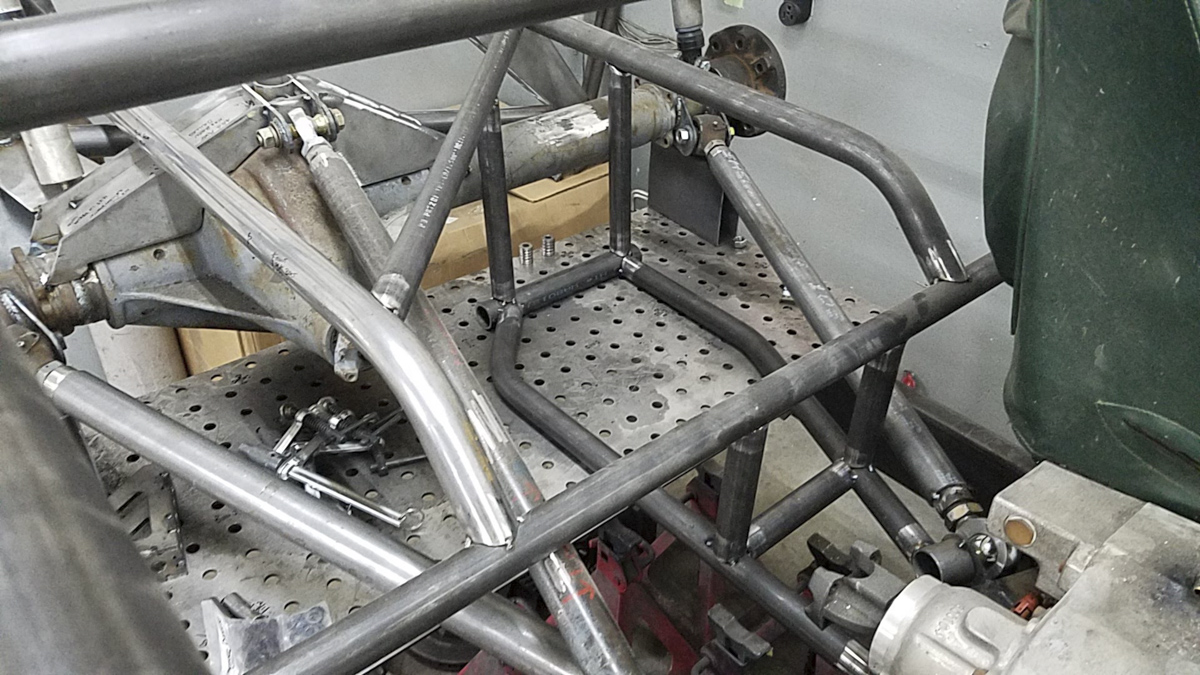

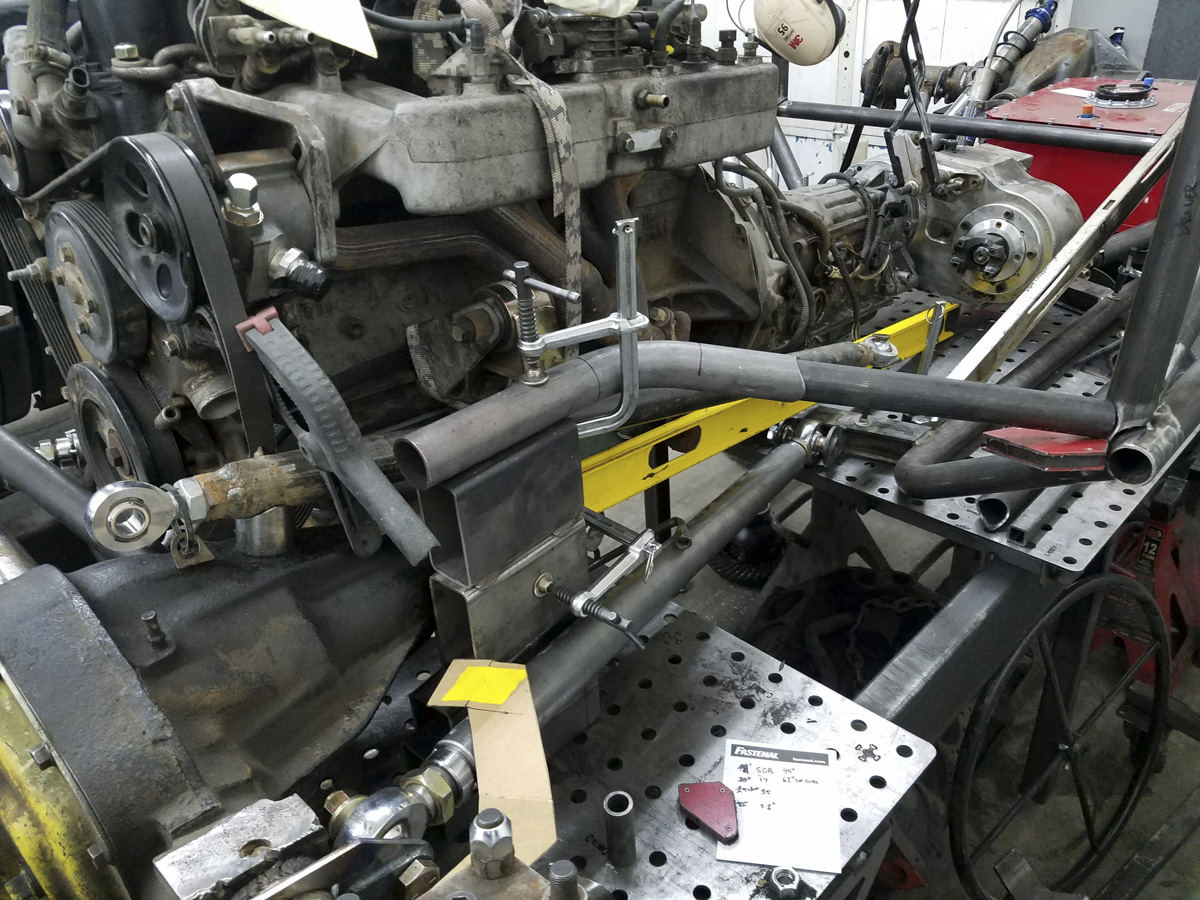

For this car, Patrick and I built the same suspension subframe and cradle that is the basis for his FTH line of buggy chassis but added 4” in between the front and rear suspension cross members. The cross members are made from 3/16” cold roll plate, with integrated lower control arm mounts and skid plate mounting bolts. These bolt hole index well into the Those Guys Rod and Customs chassis table, providing a reliable “locked-in” basis for measurements during the chassis building process. On a long weekend, Phil came up, and we disassembled his then running Cherokee buggy for parts. Once we’d stripped the 4.0L, AW4 transmission, and Atlas II transfer case from the old chassis, and set the drivetrain and axles on the table, this was now a real project, and the new buggy “Stella” was underway.

Somewhere along the way, Phil acquired a free super-wide Dana 70HD. We opted to sell his existing 14 bolt and modify the Dana 70, narrowing it and off-setting the differential far to the passenger side. Doing so takes advantage of the fact that when the tire climbs and lifts the axle tube with it. The closer the differential is to the tire, the more the center section is also lifted up. This approach also allowed us to make room for the gas tank at belly-pan level, nestled between the back of the sub-frame and the front of the rear axle, in between the three-link with panhard rear suspension links. This was a borrowed idea from Jesse Haines at JHF, and has proven successful in his pro-modified car “Pokey” and my own pro-modified car. This gets weight lower and extends the belly length of the car, in some ways preventing the rear axle from “hooking” on rocks. In this car, it also puts the fuel cell under the rear-seat instead of behind it, freeing up precious cargo room. A custom low profile truss and a few tabs finished out the rear axle setup.

On the front Dana 60, all the existing link tabs and truss were cleaned off, and a custom low profile truss was built around the pinion and caster angles and the chassis interference at full compression. Slightly off-setting the shocks to the backside of the axle lowered the overall shock assembly, making room to have the 14” coilovers just peeking above the hood line.

Fitting the passenger compartments and lower frame section using 1.75x.120 DOM tubing was performed with the axles at full compression. After fabricating the remainder of the suspension tabs and linkage, the rig was lifted off the table and the suspension was cycled. This determined the final location and design of the upper shock mounts. Some additional triangulating and support tube work in 1.5 x .095 wall, 1.5x .120 wall and 1.25x.095 wall was added while the professional fabrication tools were readily available at Those Guys Rod and Customs. Seat mounts, the gas tank framework, an oil pan skid plate, the radiator mount, and winch mount soon followed.

In late summer 2019, a combination of progress on the buggy and Patrick needing his frame table back determined it was time for the next phase. This required pulling the car off the table, disassembling installed components, final welding all available joints, painting the chassis, and re-assembly of enough pieces to winch the entire project onto the trailer. From there, it was off to my house for the finish work. The decision to paint the chassis at this phase, knowing a large number of mounting tabs had yet to be placed, was made to allow the core of the car not to require disassembly in the future. Minor paint removal in the attachment area, and re-application after welding accomplishes these goals.

“A buggy is about half done when you take it off the frame table, and it is a roller,” Patrick said to me at some point. When I took the buggy home, I’d logged approximately 280 hours of nights and weekends, some more productive with many items accomplished, and some less productive with more garage racing and sharing ideas going on.

At the time of writing this article, my plans, for now, are to finish tightening the fluid systems connections, add fluids, and attempt to start the new buggy. Expect a follow-up article showing the completed car in the next few issues.

Technical specs:

Engine: Jeep 4.0L inline 6

Transmission: AW4 with RADesigns stand alone winters shifter

Transfercase: Advance Adapters Atlas II, 3.8:1 low range gears

Front axle: Narrowed mid 80’s Ford Dana 60, 4340 shafts, clearance for additional steering, CTM u-joints, Reid Racing knuckles, WFO concepts high steer arms, RPM off road drive flanges, 4.88 gears and a spool

Rear Axle: Custom narrowed (offset) Dana 70HD, 4.88 gears, ARB air locker, Custom length Mosier axle 4340 axle shafts.

Front suspension: 3 link with panhard, 14” Fox 2.0 reservoir coilovers

Rear suspension: 3 link with panhard, 16” Fox 2.0 reservoir coilovers

Wheels / tires: 17” Raceline beadlocks, 37×12.5r17 Sticky Maxxis Trepadors

110” wheelbase, 17.5” belly, 70” overall height, and 6” uptravel.

“Dude, that really is a nice rig.” Part 2, Part one featured in Issue 33

Photos and Story by Bryan Bennett

In case you missed it, I’d taken a recycled Jeep XJ firewall buggy, stripped all the worthwhile parts off, cut down a Dana 70HD rear axle, and fabricated the chassis to roller status. My long-time friend, Phil Weeks, trusted me to deliver a functioning buggy that met his vision of the ideal rock crawler. I enlisted tons of help from Patrick McAuliffe and the folks at Those Guys Rod and Customs in Bremerton, Washington, sharing some shop space and a few beverages to get the buggy this far.

Maintaining the criteria: 4-seat, hammers cruising, Fordyce trail camping, W.E. Rock Pro-Mod legal rig, work continued on my property. Working through the “to do” list, I started on the front floor pans and interior engine doghouse. Key to this rig was easy access for maintenance or repair for the car’s critical components – because we all know how precious weekend time is. Who wants to spend more of it wrenching than wheeling?

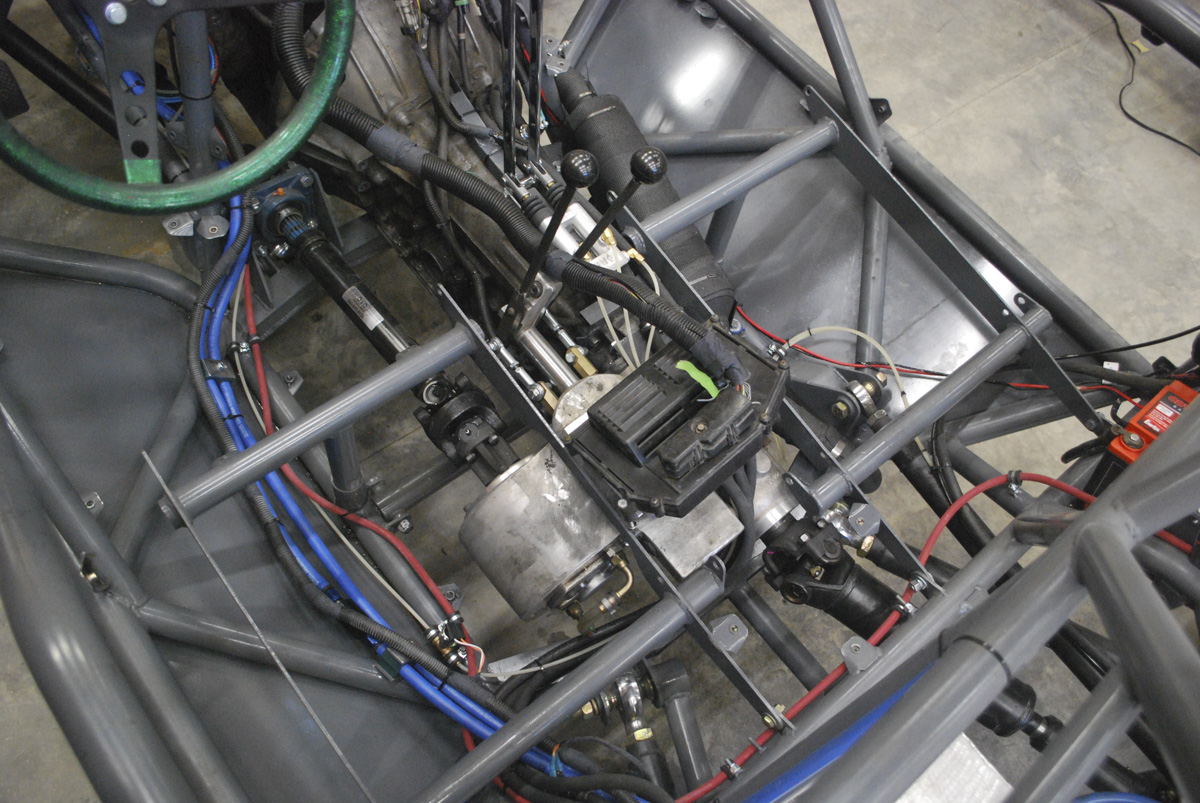

Fabricating the interior out of mostly 1/8” aluminum allowed the panels to be self-supporting, minimizing interior pieces to disassemble and remove during maintenance or component replacement. The front seat subframes are removable, which allows for quick disassembly of the cars mid-section, leaving it wide open for access. The back seat tins were next and included panels to keep smaller hands out of moving suspension components, driveshafts, places where tires cycle, and protect from mud and rocks tossed up from the tires. The rear floor pan covered the fuel tank and fuel plumbing and the driver’s side interior panel boxes in the transmission cooler and fan. The passenger side interior panel covered the AGM battery, the ARB compressor, and provided an opportunity to build a custom mount for a day-trip cooler – to be filled with juice boxes and kid snacks.

Once the steering column and steering wheel were placed, the transmission shifter found a home in close proximity, to enable those panic reverse shifts. Rory at RADesigns assisted with rebuilding a second-hand, modified Winters Shifter to control the semi-electronic AW4 transmission. The cutting brakes were mounted at the top of the transmission case, with the handles stuck through the console. The Atlas II transfer case shifters were modified to a forward position that was more comfortable for the operator, and the linkage was upgraded to heims and bolts over the plastic bushings and E-clips. Two cup holders finished out the center console aluminum work.

With the steering column in place, the hydraulic steering orbital was mounted, and some steering u-joints rounded out the mechanical linkage connections. Sneaking the gas pedal around the steering linkage finished out the operator controls. I fabricated a custom fuel cell from 1/8” aluminum to fit under the rear seat holding approximately 13 gallons that held an in-tank fuel pump for an early LS truck motor. This pump was chosen for its availability at any parts store, its integrated fuel sump and integrated pressure, return and vent fittings – minimizing tank penetrations. The tank has a fill inlet and a vent to use the (modified) factory XJ fill assembly with a factory XJ gas cap.

Plumbing used all high quality, proven parts. The fuel system used Parker Push-Lok 3/8 line, with ball valves on the feed, return, and tank vent (blue). The brakes used the Speedway Motors nylon brake lines with compression fittings.

Transmission cooling, venting, and transfer case venting used additional Push-Lok hoses and fittings (black). The ARB 4mm black hose was used from the compressor to the rear axle. The local hydraulic shop provided fabric coated 3500psi working pressure hose with user-tightened fittings to complete the steering hydraulic circuits (blue with black stripe). A modified radiator (with power steering cooler mount) and some shortened factory XJ radiator hoses finished out the front end. All lines were mounted with the appropriately sized Adel clamp or tube routing clamps. The factory XJ harness was cut down, un-needed wiring was removed, and the power distribution center was retained. Many of the fuses and relays were re-purposed for the needs of the buggy. The plumbing and wiring were custom-fitted to run down the driver’s side of the belly pan to keep them out of the way during operation and maintenance. 3/16” steel skid plates from the oil pan sump to the back of the fuel tank created a smooth flat belly for the entire vehicle. The center skid plate is bolted on to allow the transmission to be removed from underneath the buggy.

Tossing a single coil on the coilovers, with the slider stop all the way down, allows you to calculate a car’s sprung corner weight. This is helpful when deciding on spring rates. Using the known spring rate, the uncompressed (free) length of the spring, then measuring to find the compressed length of the spring is all that is needed.

Free length [inches] – compressed length [inches]) X spring rate [lbs per inch] provides that corner sprung weight.

We were pleasantly surprised with the estimated sprung corner weights of driver front – 531lbs, pass front – 625, driver rear – 468, passenger rear – 506.

As long-time members of North American XJ Association (NAXJA), and with additional inspiration from Phil’s other XJ – a 1989 Jeep Wagoneer that his father bought brand new and has been in the family since – we decided XJ skins and a Wagoneer theme were appropriate. Some eBay replacement fenders were modified to fit the front of the car, combined with a cut down factory sheet metal hood. A custom cowl was fabricated from 1/8” Aluminum, and an XJ Wagoneer trim narrowed 21 slot grill with 4ea headlights rounded out the front clip.

Side panels were templated in cardboard and cut from 0.090” thick Lexan with a careful hand on the jigsaw. Rear corners were fabricated from 1/16” aluminum and formed to match the corner of the chassis. A tailgate was cut from 1/8” aluminum to hold the stop and tail lights.

Continuing to assist with the project, Evan Elevado (lead fabricator and body shop manager at Those Guys Rod and Customs) agreed to bodywork the panels and shot them in factory 1989 Wagoneer white. The passenger door panel was intentionally left clear to increase driver visibility

One final detail that Phil requested was an intercom and race radio system integrated into the car, so his family could talk to each other and listen to Baby Shark or Johnny Cash (depending on the occupants) while on the trail. Some of the first money Phil spent on parts was on the Rugged Radios intercom to ensure the end-of-the-build budget didn’t eliminate the radio.

In the final days of building the car, I found a home for it and mounted it overhead. The custom race radio and intercom enclosure, easily removed when not needed, also included a glovebox to store a tire pressure gauge and other small items.

With Pat and Evan’s help at Those Guys Rod and Customs, the 1/16” aluminum roof got a custom beadroll design (aligned with the roof support tubes) before the final installation.

An additional 1/8” aluminum panel sits above the driver’s head (under the roof skin) in the event of a hard roll onto uneven ground. Final assembly included trimming all the zip tie ends, checking the bolts for tightness, checking all the fluids, operationally testing all the systems, and putting an hour of run time on the rig to ensure there weren’t any problems. I also took the opportunity to weigh the completed vehicle with fluids. Driver front – 1018.8lbs, Passenger front – 961.8lbs, Driver rear – 734lbs, Passenger rear – 685.3lbs for a total of 3399.9lbs – which was exciting for a 4.0L, AX-15, Atlas II, Dana 60, Dana 70, 4 seat, coilover rig.

As the project came to a close (after approximately 600 hours of Social Distortion Radio on Pandora) and items were scratched off the list, transport was arranged. A trip was planned to Bend, OR, for a long weekend of wheeling with the #Sketchyoregonboys, and delivery of the completed buggy. If you see Phil on the trails – take a look, and if you think it is – be sure to tell him, “Dude – That’s a nice rig!” [Photos Final1, Final2, Final3]

Bryan Bennett is an engineer, driver of the #91 Pro-Mod (The Banquet Buggy), avid snowmobiler, and an amateur fabricator in Port Orchard, WA. He can be reached at [email protected].