Originally Published in Issue 29 of 4Low Magazine

Make sure to subscribe to get the newest issues of 4Low Magazine right to your mail box. CLICK HERE

By Christian Sturtz, [email protected]

Photos by Christian Sturtz

One of the most overlooked and neglected systems on vehicles is the cooling system. The cooling system affects many different systems of the vehicle, including: engine performance, vehicle emissions, transmission, and the a/c system. There are several components that make up a cooling system, including: the object you are trying to cool (engine), water pump, thermostat, temperature sensor, hoses, radiator, fan, shroud, overflow/recovery tank, coolant, etc.

The water pump circulates the coolant through the cooling system, while the thermostat helps to regulate the operating temperature of the engine. The thermostat also helps with vehicle emissions and allows the vehicle to get warm enough to produce heat for passengers. Temperature sensors let the driver and computer know what is going on and they can be used in controlling electric fans. Hoses connect components in the cooling system while the radiator gives the coolant a large surface area for heat transfer. The fan pulls air through the radiator and helps with the heat transfer as well. The fan shroud directs and funnels air from the fan through the radiator. Meanwhile, the overflow/recovery tank allows expansion and contraction of coolant in the system. Coolant is a 50/50 mix of water and antifreeze. Antifreeze is mostly glycol based (though that is changing), which helps keep the water from freezing; it also has a lubrication and anti-rusting agent in it. Lastly, other components can be included in coolant systems, such as a heater core.

Now the reassembly begins! The Flow Kooler water pump’s design is different to increase performance. You can see by the pictures their design differences. The steel tube must be removed from the original pump and reinstalled on the new pump. Make sure to test fit the pump for tube position before trying to bolt it into place. It is always a good idea to use thread sealant on the steel tube threads as well as the water pump/thermostat housing bolts. Then clean up the thermostat housing, install the thermostat, and heater hoses.

Now the reassembly begins! The Flow Kooler water pump’s design is different to increase performance. You can see by the pictures their design differences. The steel tube must be removed from the original pump and reinstalled on the new pump. Make sure to test fit the pump for tube position before trying to bolt it into place. It is always a good idea to use thread sealant on the steel tube threads as well as the water pump/thermostat housing bolts. Then clean up the thermostat housing, install the thermostat, and heater hoses.

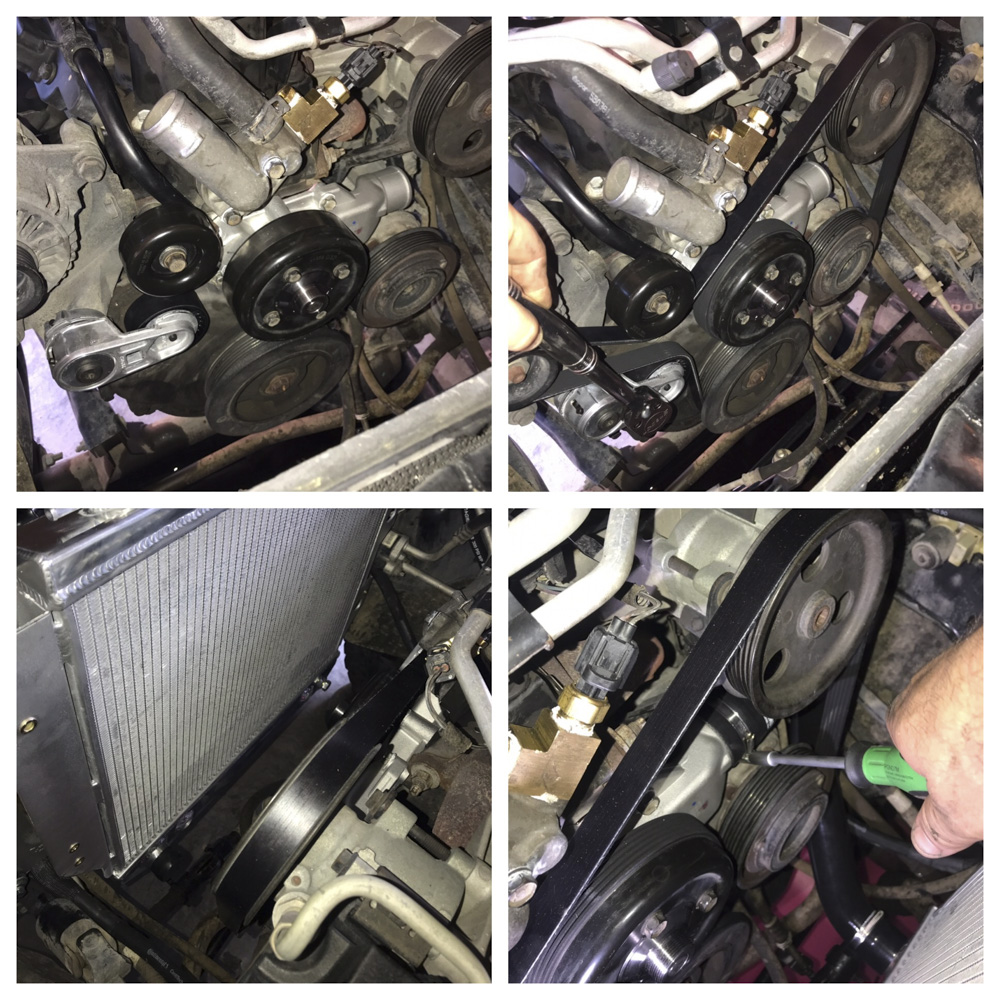

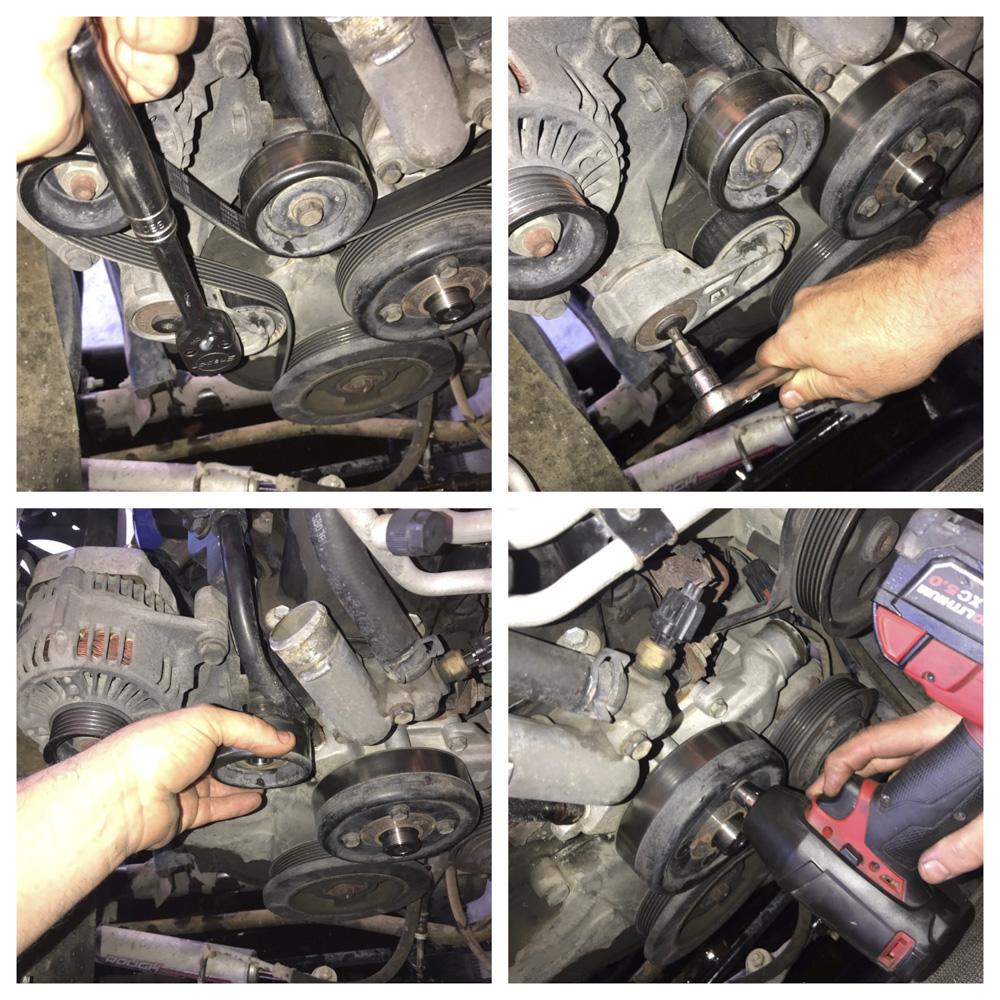

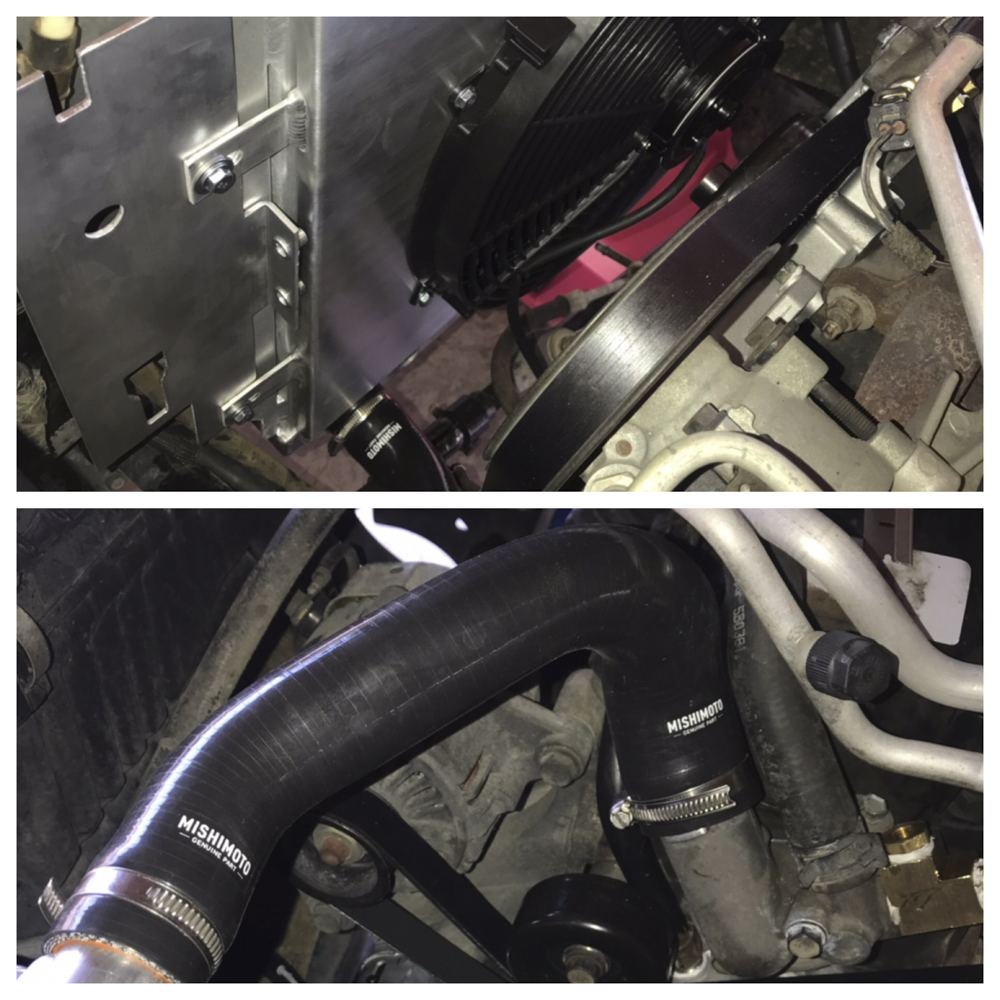

The water pump pulley, new tensioner, idler, and belt were installed. It’s a good idea to place thread lock compound to the pulley bolts. The radiator was then bolted into place and the lower hose was installed

Finally, the vehicle is filled with coolant and bled properly. Now you have a vehicle that will run much better because you took time out to cool it off.

Sources:

Mishimoto Automotive Flow Kooler

18 Boulden Circle, Suite 14 500 Linne Road, Unit 1

New Castle, DE 19720 Paso Robles, CA 93446

- 466.4744 805.239.2501

www.mishimoto.com www.flowkoolerwaterpumps.com

Napa Auto Parts AutoZone

800.538.6272 800.288.6966

www.napaonline.com www.autozone.com

Parts Used:

Mishimoto:

Radiator (MMRAD-WRA-87)

Fan/Controller (MMFS-WRA-87NPT)

Hose Kit (MMHOSE-WR6-97BK)

Flow Kooler:

Water Pump (1750)

Napa:

Temperature Sensor (TS3005)

Belt (K060882)

Idler Pulley (38043)

Tensioner Assembly (38163)

Auto Zone:

Thermostat (15359DLG)